AICI

DownloadDatasheet PDF AICI Indoor and outdoor Armoured industrial cable, LSZH tight buffer Application: Optical cable for industry environments. The cable ... read more

Description

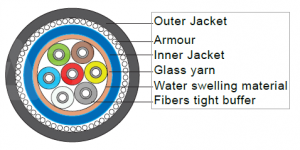

AICI Indoor and outdoor Armoured industrial cable, LSZH tight buffer

| Application: Optical cable for industry environments. The cable is suitable for both indoor and outdoor use. Continuos submergence in water is not recommended. Outer jacket made of UV- and weather resistant material may be exposed for shorter periods to fluids such as diesel and mineral oils (acc. to IEC 60811-2-1). The cable is reinforced with a steel wire braiding between the two jackets. Strength elements of glass yarn around the cable core allow easy installation of long lengths. The 0,9mm tight buffer is easy to strip allowing fast and reliable splicing and connector mounting. Each fibre is color coded for easy identification. Outer jacket is marked to show fibre type and cable type. The cable is DNV approved. |

|||||||||||

| Specifications: Temperature installed: -30 to +70 [°C] Temperature @ installation: -10 to +70 [°C] Tensile perforemance IEC 60794-1-2-E1: for 4 and 8 fibre: 1000 [N] for 12 fibre: 1500 [N] for 24 fibre: 2000 [N] Crush, acc IEC 60794-1-2E3: 2000 [N/10cm] Impact, acc IEC 60794-1-2E4: 1 impacts, 25J Torsion, acc IEC 60794-1-2E7: ± 1 turns/1m Water tightness acc. IEC 60794-1-2F5B: < 3m/24hours Min. bending radius fixed: 15 x outer diam Min. bending radius flexible: 10 x outer diam Cable bend (IEC 60794-1-2E11): <0.5dB/±5 turn Flexibility (IEC 60794-1-2E8): 1000 cycles |

| Fire and smoke classifications: IEC 60332-3-22 and IEC 60332-1-2 IEC 61034-1/2 IEC 60754-1/2 |

|||||||||||

| Chemical resistance: Mineral oils – IRM 902 (IEC 60811-2-1): 7days/23°C 4hours/70°C Diesel – IRM 903 (IEC 60811-2-1) 7days/23°C 4hours/70°C |

|||||||||||

| Approvals: DNV- and ABS-certified |

| Construction: Fibers: Tight buffer, Ø=0,9mm Colour of tight: 1 – blue 13 – blue with black ring 2 – orange 14 – orange with black ring 3 – green 15 – green with black ring 4 – brown 16 – brown with black ring 5 – grey 17 – grey with black ring 6 – white 18 – white with black ring 7 – red 19 – red with black ring 8 – black 20 – yellow with black ring 9 – yellow 21 – violet with black ring 10 – violet 22 – pink with black ring 11 – pink 23 – turquoise with black ring 12 – turquoise 24 – white with double black ring

* acc. IEC 60794-1-2E1 Filler: Glassyarn |

||||||||||||||||||||||||||||||||||||

| Multimode fibres | MM 62.5 IEC 60793-2-10 Type A1b Telecordia GR-20-core |

MM50 ITU-T G651.1 IEC 60793-2-10 Type A1a.1 Telecordia GR-20-core |

MM50-OM3 ISO/IEC 11801 IEC 60793-2-10 Type A1a.2 Telecordia GR-20-core |

MM50-OM4 ISO/IEC 11801 IEC 60793-2-10 Type A1a.2 Telecordia GR-20-core |

||||||

| ITU-T type | – | G 651 | – | |||||||

| Core Diameter | mm | 62.5 ± 2 | 50 ± 2 | 50 ± 2 | 50 ± 2 | |||||

| Core non-circularity | % | <_ 5 | <_ 5 | <_ 5 | <_ 5 | |||||

| Cladding Diameter | mm | 125 ± 1,0 | 125 ± 1,0 | 125 ± 1,0 | 125 ± 1,0 | |||||

| Coating Diameter | mm | 245 ± 5 | 242 ± 5 | 242 ± 5 | 242 ± 5 | |||||

| Cladding non-circularity | % | 0,7 | 0,7 | 0,7 | 0,7 | |||||

| Core/cladding concentricity error | mm | <_ 1,0 | <_ 1,0 | <_ 1,0 | <_ 1,0 | |||||

| Coating/cladding concentricity error | mm | <_ 10 | <_ 6 | <_ 6 | <_ 6 | |||||

| Numerical Aperture | mm | 0.275 ± 0.015 | 0.200 ± 0.015 | 0.200 ± 0.015 | 0.200 ± 0.015 | |||||

| Proorf test | kpsi | >_ 100 | >_ 100 | >_ 100 | >_ 100 | |||||

| Attenuation Bandwith |

at 850 nm | db/km (max) | <_ 3,5 | <_ 2,8 | <_ 2,8 | <_ 2,8 | ||||

| at 1300 nm | db/km (max) | <_ 1,0 | <_ 0,8 | <_ 0,8 | <_ 0,8 | |||||

| at 850 nm | MHz x km | >_ 200 | >_ 500 | >_ 1500 | >_ 3500 | |||||

| at 1300 nm | MHz x km | >_ 500 | >_ 500 | >_ 500 | >_ 500 | |||||

| Single mode fibres | Single mode SMR 9/125/250 | Single mode SMR LWP 9/125/250 | Non-zero Dispersion | |||||||

| ITU-T type | G652.B | G652.D | G655 | |||||||

| Mode Field diameter (MDF) | at 1310 nm | mm | 9.2 ± 0.4 | 9.2 ± 0.4 | – | |||||

| at 1550 nm | mm | – | – | 9.2 ± 0.5 | ||||||

| Cladding Diameter | mm | 125 ± 1 | 125 ± 0.7 | 125 ± 1 | ||||||

| Coating Diameter | mm | 245 ± 10 | 245 ± 5 | 245 ± 10 | ||||||

| Attenuation | at 1310 nm | db/km (max) | <_ 0.38 | <_ 0.35 | – | |||||

| at 1383 nm | db/km (max) | – | <_ 0.33 | – | ||||||

| at 1550 nm | db/km (max) | <_ 0.25 | <_ 0.25 | <_ 0.25 | ||||||

| at 1625 nm | db/km (max) | – | <_ 0.28 | <_ 0.28 | ||||||

| Zero dispersion wavelength | l0 | 1302 – 1322 | 1302 – 1322 | – | ||||||

| Chromatic Disper- sion PDM |

at 1285 – 1330nm | ps/nm x km | <_ 0.35 | <_ 0.35 | – | |||||

| at 1550 nm | ps/nm x km | <_ 18.0 | <_ 18.0 | – | ||||||

| at 1530 – 1565 nm |

ps/nm x km | – | – | 5.5 to 10.0 | ||||||

| at 1565 – 1625 nm |

ps/nm x km | – | – | 7.5 to 13.0 | ||||||

| at 1550 nm | ps/vkm | – | – | <_ 0.20 | ||||||