PURWIL PUR/PUR Classic Line

DownloadDatasheet PDF PURWIL PUR/PUR Classic Line Flexible low voltage cables 20_1_0 S05QQ-F / S1QQ-F Robust and flexible polyurethane cable. (PUR/PUR,... read more

Description

PURWIL PUR/PUR Classic Line

Flexible low voltage cables

20_1_0

S05QQ-F / S1QQ-F

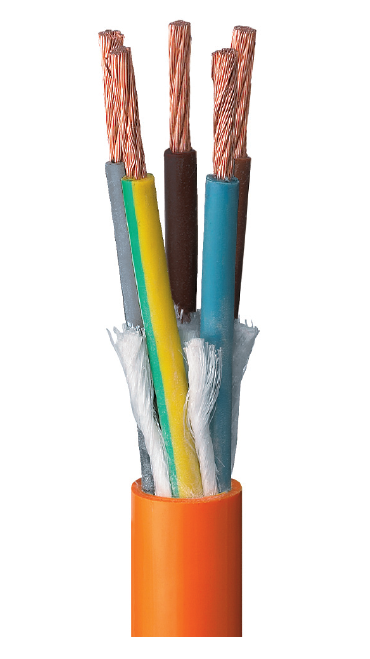

Robust and flexible polyurethane cable. (PUR/PUR, orange, flex)

Application

The PURWIL-Cable is mainly used for temporary installations under harsh environmental condi-tions. The cable has a very high resistance to friction,cold flexibility and is resistant against mineral oil,ozone and UV radiation.

Main applications:

Machine industry,construction sites,chemical industry,appliance construction and transport industry,etc.

Construction

- Copper cord flex,cl. 5 (IEC 60228) finely stranded

- Polyurethan insulation (PUR)

- Conductor colours acc. to CENELEC HD308S2

- Sheath Polyurethan (PUR)

Description

Designed acc. to SEV TP20B/3C:

- Cold bending strength test,level 4: – 40°C

- Cyclical bending test,level 3: > 60’000 single moves

- Pressure resistance,level 3: 1800 N

- Friction resistance,level 2: 1000 double strokes

- Cold strike resistance,level 4: – 40°C

- Weather/water resistance,level 2:

- Oil resistance: level 2

- Nominal voltage

≤ 1mm2:Uo/U 300 V /500 V

≥ 1.5 mm2:Uo/U600 V/1000 V - Test voltage

≤ 1mm2:2000V/50Hz

≥ 1.5 mm2:3500V/50Hz - Min. bending radius 10 x D (D = cable-Ø)

Temperature range

– 40°C…+80°C

– 40°C…+90°C permanent installation

Jacket colour

Orange similar to RAL 2004

Standards

SEV TP20B/3C in combination with HD22.10

IEC 60754-1 halogen free

Remarks

Special labelling of outer sheath on request

Technical data

| Cross-section mm² | Part no. | Conductor design | Ø D approx. mm | Cu-number kg/km | Weight kg/km |

| 2×0.75 | 18375 | LN | 6.4 | 14.40 | 41.0 |

| 3×0.75 | 18376 | LNPE | 6.7 | 21.60 | 53.0 |

| 4×0.75 | 18377 | 3LPE | 7.8 | 28.80 | 71.0 |

| 2×1.0 | 18379 | LN | 6.8 | 19.20 | 47.0 |

| 3×1.0 | 18380 | LNPE | 7.0 | 28.80 | 61.0 |

| 4×1.0 | 18381 | 3LPE | 8.0 | 38.40 | 81.0 |

| 5×1.0 | 18382 | 3LNPE | 8.8 | 48.00 | 97.0 |

| 7×1.0 | 18383 | 6Lnum+PE | 10.9 | 67.20 | 143.0 |

| 12×1.0 | 18384 | 11Lnum+PE | 13.4 | 115.20 | 215.0 |

| 2×1.5 | 18386 | LN | 7.8 | 28.80 | 64.0 |

| 3×1.5 | 18351 | LNPE | 8.3 | 43.20 | 87.0 |

| 4×1.5 | 18387 | 3LPE | 9.4 | 57.60 | 115.0 |

| 5×1.5 | 18388 | 3LNPE | 10.5 | 72.00 | 142.0 |

| 7×1.5 | 18389 | 6Lnum+PE | 12.8 | 100.80 | 198.0 |

| 12×1.5 | 18390 | 11Lnum+PE | 15.0 | 172.80 | 302.0 |

| 3×2.5 | 18406 | LNPE | 10.2 | 72.00 | 138.0 |

| 4×2.5 | 18407 | 3LPE | 11.4 | 96.00 | 177.0 |

| 5×2.5 | 18352 | 3LNPE | 12.6 | 120.00 | 217.0 |

| 7×2.5 | 18408 | 6Lnum+PE | 15.5 | 168.00 | 308.0 |

| 3×4 | 18421 | LNPE | 12.3 | 115.20 | 208.0 |

| 4×4 | 18422 | 3LPE | 13.6 | 153.60 | 265.0 |

| 5×4 | 18423 | 3LNPE | 15.1 | 192.00 | 328.0 |

| 7×4 | 18424 | 6Lnum+PE | 18.1 | 268.80 | 450.0 |

| 4×6 | 18436 | 3LPE | 16.0 | 230.40 | 376.0 |

| 5×6 | 18437 | 3LNPE | 17.4 | 288.00 | 460.0 |

| 4×10 | 18439 | 3LPE | 20.0 | 384.00 | 608.0 |

| 5×10 | 18451 | 3LNPE | 22.1 | 480.00 | 745.0 |

| 4×16 | 18453 | 3LPE | 23.3 | 614.40 | 879.0 |

| 5×16 | 18353 | 3LNPE | 25.9 | 768.00 | 1100.0 |