TITANEX 90°C H07 RN-F

DownloadDatasheet PDF TITANEX 90°C H07 RN-F Flexible rubber cable Industrial fl exible cable, insulation and outer sheath in elastomer. Oil... Lees meer

Beschrijving

TITANEX 90°C H07 RN-F

Flexible rubber cable

Industrial fl exible cable, insulation and outer sheath in elastomer.

Oil resistant, fl ame retardant according to IEC/EN 60332-1-2 standard. H07RN-F

APPLICATION

The TITANEX® flexible rubber cable range off ers exceptional performances and is designed to release you from all your constraints. Robust yet fl exible, TITANEX® is easy to use and withstands the toughest of conditions, such as hard-wearing situations, extreme temperatures and most chemicals. For more than 50 years the TITANEX® cable range properties have been recognized as the best choice for all mobile and fi xed installations in industrial environments such as construction sites, cranes, machines tools, factories, generators etc.

TITANEX® is also suitable for public environments and temporary events such as festivals or sports competitions, where the cable is often laid directly on the ground with no protection.

The cable may be rated 0,6/1 kV where the installation has built-in protection and for motors in lifting appliances – machine tools – etc.

INSTALLATION

This cable can be installed in open air or be buried but with extra mechanical protection.

STRUCTURE

Conductor: Copper conductor, bare, fl exible (class 5) according to DIN VDE 0295 and IEC 60228 cl. 5, HD 383

Cores: Cross-linked elastomer insulation

Outer sheath: Cross-linked elastomer with high mechanical properties

TECHNICAL DATA

Nominal voltage: 450V/750V

Test voltage: 2500 V

Conductor resistance: According to DIN VDE 0295 cl. 5

Conductor temperature: fixed and protected installation: 90°C, mobile installation: 60°C

Short-circuit temperature: max.+200°C on the conductor

Operating temperature: -25°C to +55°C

Min. bending radius: 6 to 8x cable outer diameter

Dynamic use: 3x outer cable diameter if the outer diam is < or =12mm

Static use: 4x outer cable diameter if the outer diam is >12mm.

Permanent tensile loading: (total copper cross section in mm2) max. 15N/mm2

Silicon free: yes

TESTS ACCORDING TO DIN VDE 0472 AND IEC:

Flammability: Test method B according to VDE 0472 part 804 and IEC 332-1

Oil resistance: Test method A acc. to VDE 0472 part 803 or test method C acc. to part 805A1

Ozone resistance:Test method A according to VDE 0472 part 805

CONDUCTOR MARKING

| number of conductors | with green-yellow conductor | with green-yellow conductor |

| 1 | black | |

| 2 | brown + blue | |

| 3* | green-yellow + brown + blue | brown + black + grey |

| 3** | blue + brown + black | |

| 4 | green-yellow + brown + black + grey | blue + brown + black + grey |

| 5 | green-yellow + blue + brown + black + grey | blue + brown + black + grey + black |

| > 5 | white printed numbers + 1 green-yellow | white printed numbers |

| * for cables without green/yellow, with one cross section >4mm² ** for the cables without green/yellow, with a cross section of 1,5mm² & 2,5mm² |

||

| Item H07 RN-F |

max.current (A) 90°C |

current rating open air (A) |

Voltage drop (V/A.km) |

Cu weight | Outer diameter min.(mm) – max.(mm) |

weight (kg/km) |

| 1×1,5 | 24 | 14,4 | 7,1 | 50 | ||

| 1×2,5 | 33 | 24,0 | 7,9 | 66 | ||

| 1×4 | 45 | 38,0 | 9,0 | 94 | ||

| 1×6 | 58 | 58 | 5,90 | 58,0 | 7,9 – 9,8 | 109 |

| 1×10 | 80 | 80 | 3,40 | 96,0 | 9,5 – 11,9 | 182 |

| 1×16 | 107 | 107 | 2,20 | 154,0 | 10,8 – 13,4 | 256 |

| 1×25 | 138 | 138 | 1,40 | 240,0 | 12,7 – 15,8 | 369 |

| 1×35 | 169 | 169 | 1,04 | 336,0 | 14,3 – 17,9 | 482 |

| 1×50 | 207 | 207 | 0,75 | 480,0 | 16,5 – 20,6 | 662 |

| 1×70 | 268 | 268 | 0,56 | 672,0 | 18,6 – 23,3 | 895 |

| 1×95 | 328 | 328 | 0,44 | 912,0 | 20,8 – 26,0 | 1144 |

| 1×120 | 382 | 382 | 0,36 | 1152,0 | 22,8 – 28,6 | 1430 |

| 1×150 | 441 | 441 | 0,31 | 1440,0 | 25,2 – 31,4 | 1740 |

| 1×185 | 506 | 506 | 0,28 | 1776,0 | 27,6 – 34,4 | 2160 |

| 1×240 | 599 | 599 | 0,23 | 2304,0 | 30,6 – 38,3 | 2730 |

| 1×300 | 693 | 693 | 0,20 | 2880,0 | 33,5 – 41,9 | 3480 |

| 2×1 | ||||||

| 2×1,5 | 26 | 26 | 27 | 29,0 | 8,5 – 11,0 | 111 |

| 2×2,5 | 36 | 36 | 16,2 | 48,0 | 10,2 – 13,2 | 161 |

| 2×4 | 49 | 49 | 10,1 | 77,0 | 11,8 – 15,1 | 238 |

| 2×6 | 63 | 63 | 6,7 | 115,0 | 13,1 – 16,8 | 279 |

| 2×10 | 86 | 86 | 3,8 | 192,0 | 17,7 – 22,6 | 538 |

| 2×16 | 115 | 115 | 2,5 | 308,0 | 20,2 – 25,7 | 744 |

| 3G1 | 20 | 39,4 | 29,0 | 8,3 – 10,7 | 117 | |

| 3G1,5 | 26 | 26 | 27,0 | 43,0 | 9,2 – 11,9 | 134 |

| 3G2,5 | 36 | 36 | 16,2 | 72,0 | 10,9 – 14,0 | 195 |

| 3G4 | 49 | 49 | 10,1 | 115,0 | 12,7 – 16,2 | 290 |

| 3G6 | 63 | 63 | 7,0 | 173,0 | 14,1 – 18,0 | 346 |

| 3G10 | 86 | 86 | 4,0 | 288,0 | 19,1 – 24,2 | 663 |

| 3G16 | 115 | 115 | 2,5 | 461,0 | 21,8 – 27,6 | 924 |

| 3G25 | 149 | 720,0 | ||||

| 3G35 | 185 | 185 | 1,21 | 1008,0 | 29,3 – 37,1 | 1760 |

| 3G50 | 225 | 225 | 0,87 | 1440,0 | 34,1 – 42,9 | 2390 |

| 3G70 | 289 | 289 | 0,64 | 2016,0 | 38,4 – 48,3 | 3110 |

| 3G95 | 352 | 352 | 0,5 | 2736,0 | 43,3 – 54,0 | 4170 |

| 3G120 | 410 | 3456,0 | 5078 | |||

| 4G1 | 18 | 34,08 | 38,0 | 9,6 – 12,0 | 144 | |

| 4G1,5 | 23 | 23 | 23,3 | 58,0 | 10,2 – 13,1 | 165 |

| 4G2,5 | 31 | 31 | 14,0 | 96,0 | 12,5 – 15,5 | 245 |

| 4G4 | 42 | 42 | 8,71 | 154,0 | 14,0 – 18,0 | 357 |

| 4G6 | 54 | 54 | 5,84 | 230,0 | 15,7 – 20,0 | 443 |

| 4G10 | 75 | 75 | 3,42 | 384,0 | 20,8 – 26,5 | 818 |

| 4G16 | 100 | 100 | 2,20 | 614,0 | 23,8 – 30,1 | 1150 |

| 4G25 | 127 | 127 | 1,44 | 960,0 | 28,9 – 36,6 | 1700 |

| 4G35 | 158 | 158 | 1,04 | 1344,0 | 32,5 – 41,1 | 2180 |

| 4G50 | 192 | 192 | 0,75 | 1920,0 | 37,7 – 47,5 | 3030 |

| 4G70 | 246 | 246 | 0,56 | 2688,0 | 42,7 – 54,0 | 3990 |

| 4G95 | 298 | 298 | 0,44 | 3648,0 | 48,4 – 61,0 | 5360 |

| 4G120 | 346 | 346 | 0,36 | 4608,0 | 53,0 – 66,0 | 6500 |

| 4G150 | 395 | 395 | 0,31 | 5760,0 | 58,0 – 73,0 | 7990 |

| 4G185 | 450 | 7104,0 | 9912 | |||

| 5G1,5 | 23 | 23 | 23,6 | 72,0 | 11,2 – 14,4 | 238 |

| 5G2,5 | 31 | 31 | 14,0 | 120,0 | 13,3 – 17,0 | 297 |

| 5G4 | 42 | 42 | 8,72 | 192,0 | 15,6 – 19,9 | 453 |

| 5G6 | 54 | 54 | 5,84 | 288,0 | 17,5 – 22,2 | 557 |

| 5G10 | 75 | 75 | 3,43 | 480,0 | 22,9 – 29,1 | 1001 |

| 5G16 | 100 | 100 | 2,20 | 768,0 | 26,4 – 33,3 | 1430 |

| 5G25 | 127 | 127 | 1,44 | 1200,0 | 32,0 – 40,4 | 2096 |

| 5G35 | 158 | 158 | 1,04 | 1680,0 | 35,6 – 45,1 | 2690 |

| 5G50 | 192 | 192 | 1,04 | 2400,0 | 41,8 – 53,0 | 3840 |

| 5G70 | 246 | 246 | 0,56 | 3360,0 | 47,5 – 60,0 | 4996 |

| 7G1,5 | 17 | 23,3 | 101,0 | 14,7 – 18,7 | 349 | |

| 7G2,5 | 21 | 13,9 | 168,0 | 17,1 – 21,8 | 487 | |

| 12G1,5 | 12 | 23,3 | 173,0 | 17,6 – 22,1 | 510 | |

| 12G2,5 | 16 | 13,9 | 288,0 | 20,6 – 26,2 | 702 | |

| 14G1,5 | 202,0 | 600 | ||||

| 18G1,5 | 10 | 20,7 | 259,0 | 20,7 – 26,3 | 730 | |

| 18G2,5 | 14 | 13,9 | 432,0 | 24,4 – 30,9 | 1018 | |

| 19G1,5 | 274,0 | 819 | ||||

| 19G2,5 | 456,0 | 1170 | ||||

| 24G1,5 | 346,0 | 1005 | ||||

| 24G2,5 | 576,0 | 1380 | ||||

| 27G1,5 | 385,0 | 1077 | ||||

| 27G2,5 | 638,0 | 1521 | ||||

| 36G1,5 | 518,0 | 1260 | ||||

| 36G2,5 | 864,0 | 1862 | ||||

| 37G1,5 | 533,0 | 1370 |

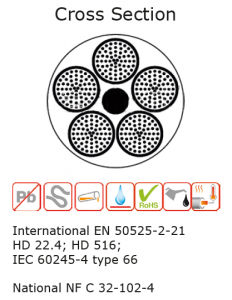

SPECIAL ATTRIBUTES

Coating colour: Black

Standards: International EN 50525-2-21; HD 22.4; HD 516; IEC 60245-4 type 66; National NF C 32-102-4

Bureau Veritas Marine & Offshore Approval: 18999/C0 BV:

IEC 60092-350 (2014)

IEC 60092-353 (2016)

IEC 60092-360 (2014)

IEC 60811 (2012)