H01 N2-D (flexible)

DownloadDatasheet PDF H01 N2-D (flexible) welding cable APPLICATION For welding specialists with high robustness and flexibility requirements. This special cable... read more

Description

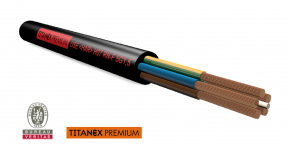

H01 N2-D (flexible)

welding cable

APPLICATION

For welding specialists with high robustness and flexibility requirements. This special cable is used to transmit high currents from electrical welding devices to welding tools. It is suitable for flexible use under extreme con-ditions, on assembly lines and handling systems, in machine tool construction, automotive manufacturing and shipbuilding and for manual and automatic arc and spot welding devices. The cable remains highly flexible even under the influence of light, ozone, inert gas, oil and oxygen. It is also resistant to high thermal loads.

STRUCTURE

Conductor: Copper conductor, bare, flexible (class 5) according to DIN VDE 0295 and IEC 60228 cl. 5, HD 383

Cores: Rubber compound insulation

Outer sheath: Cross-linked elastomer with high mechanical strength

TECHNICAL DATA

Nominal voltage: 100 V/100 V

Test voltage: 1000 V

Operating temperature: -25°C to +60°C

Max. operating temperature: +85°C

Min. installation temperature: -25°C

Max. installation temperature: +80°C

Min. bending radius: 12 x cable diameter

TESTS ACCORDING TO DIN VDE 0472 AND IEC:

Flammability: Test method B according to VDE 0472 part 804 and IEC 332-1

Welding resistance: Test for resistance against welding spatter: according to HD 22.2

Oil resistance: At 100°C, testing temperature 200°C/24h: test method A according to VDE 0472 part 803

| Product description | Cu weight | Outer Ø (mm) | Weight (kg/km) |

| H01 N2-D 16 mm² | 154.0 | 11.5 | 204 |

| H01 N2-D 25 mm² | 240.0 | 13.0 | 292 |

| H01 N2-D 35 mm² | 336.0 | 14.5 | 388 |

| H01 N2-D 50 mm² | 480.0 | 17.0 | 542 |

| H01 N2-D 70 mm² | 672.0 | 19.0 | 756 |

| H01 N2-D 95 mm² | 912.0 | 21.5 | 976 |

| H01 N2-D 120 mm² | 1152.0 | 24.0 | 1221 |

SPECIAL FEATURES

Sheath colour: Black